Lathe Speeds And Feeds Chart

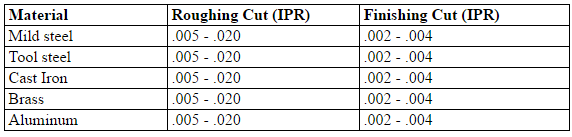

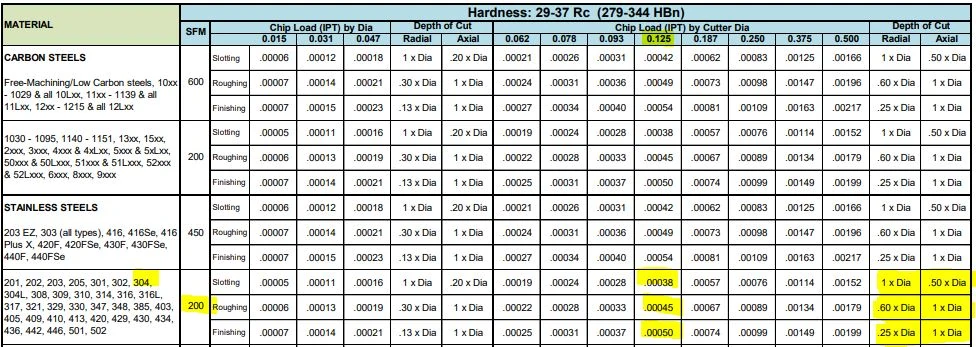

Start off using an RPM derived for the chip load for the material being cut see charts.

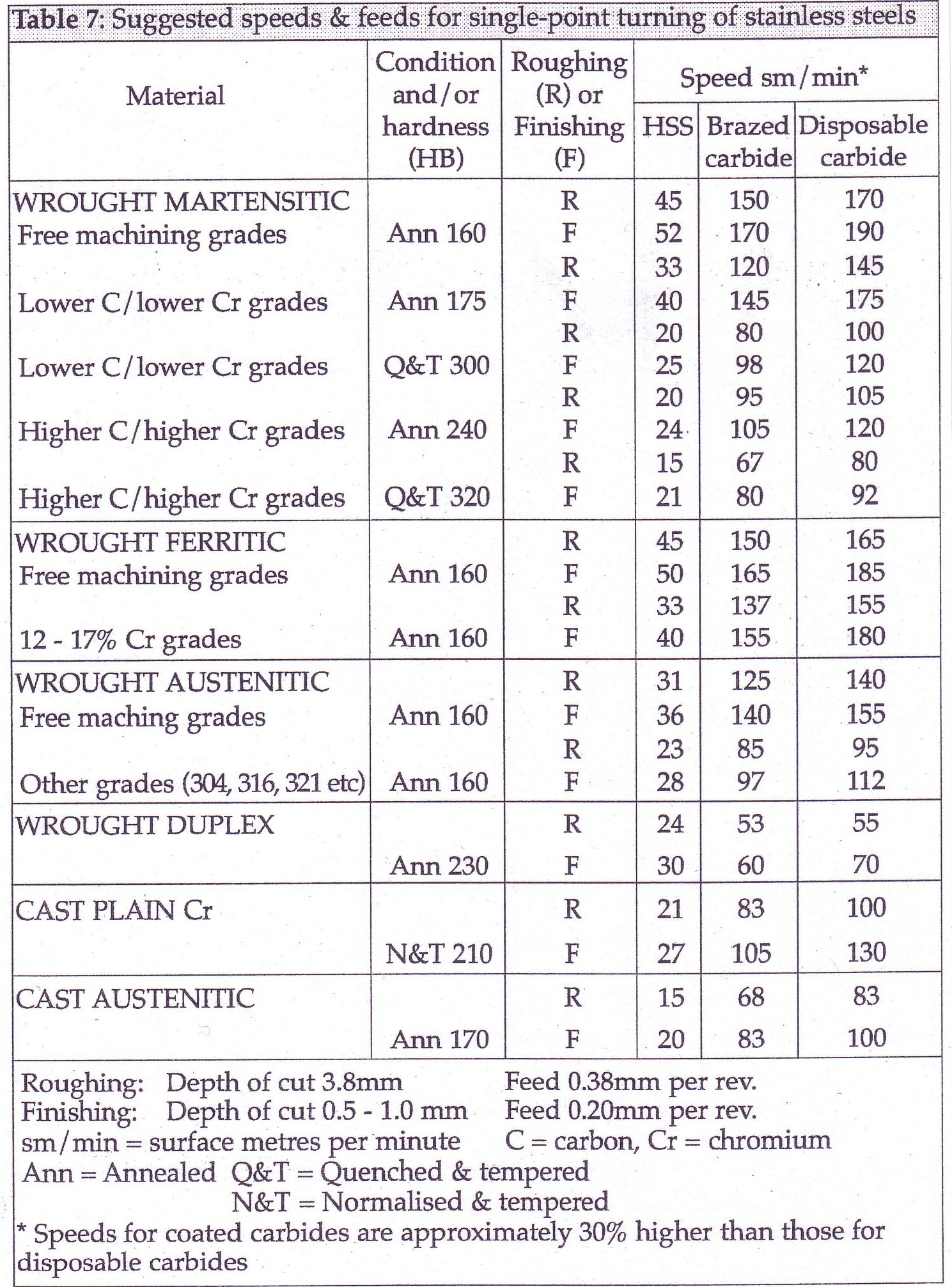

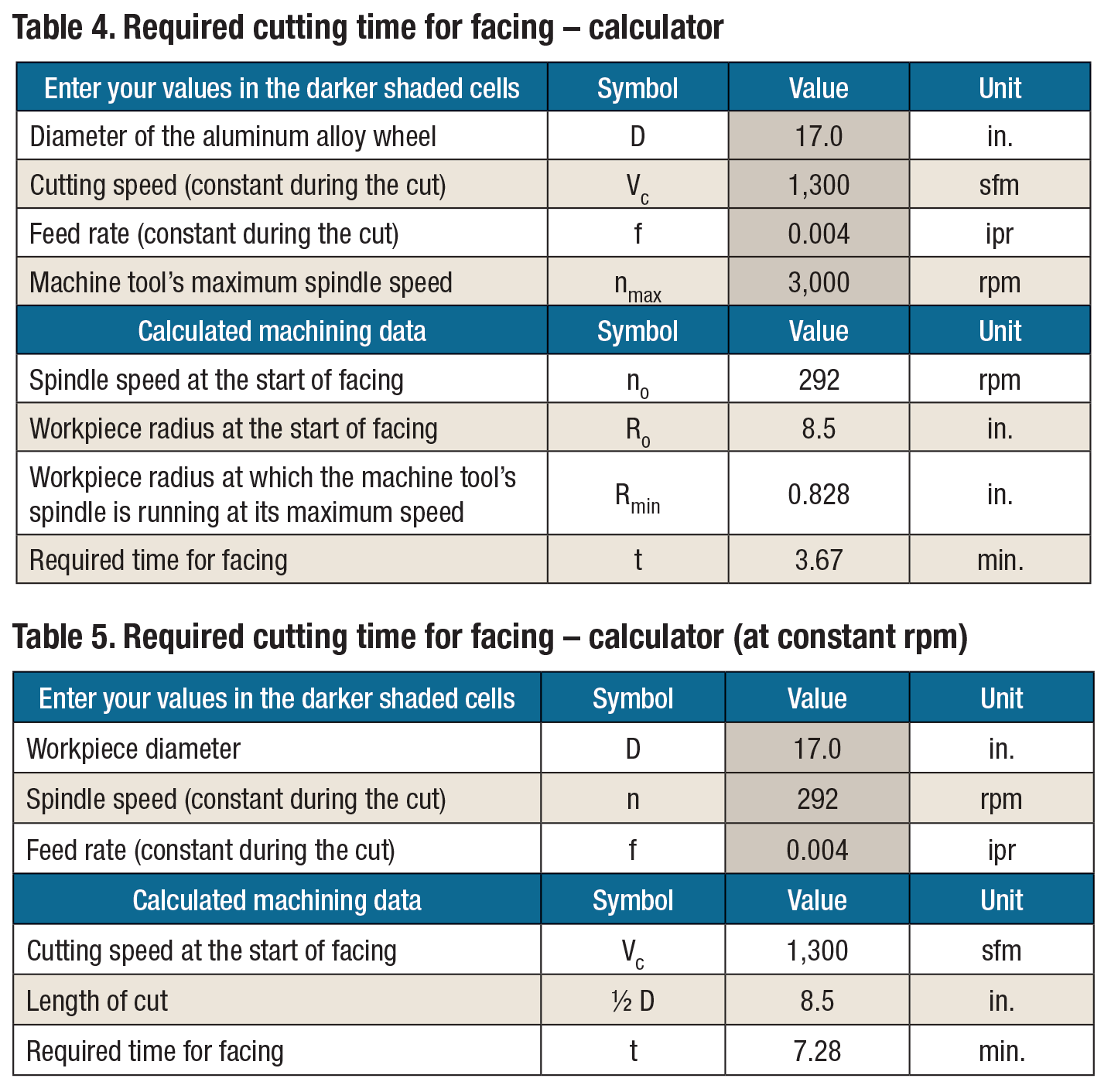

Lathe speeds and feeds chart. Based on the previous tip and theresults from Example 1A. The cutting speed is 35 metres per minute and the feed is 05mm per revolution. 12 rows Free Online Speeds and Feeds Calculator Mill Lathe CNC Router on this page.

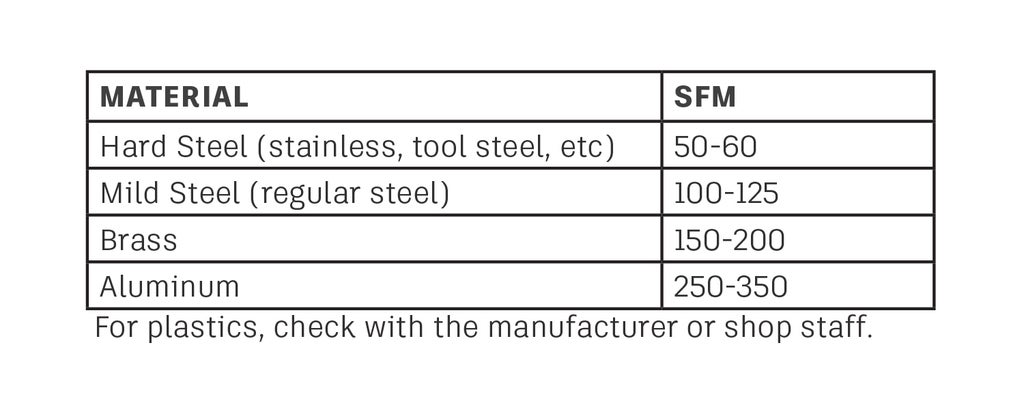

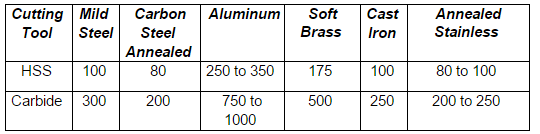

The rate at the workpiece surface measured in surface feet per minute irrespective of. Speed and Feed Calculator for Miscellaneous Applications. A cut is to be made with a high-speed steel.

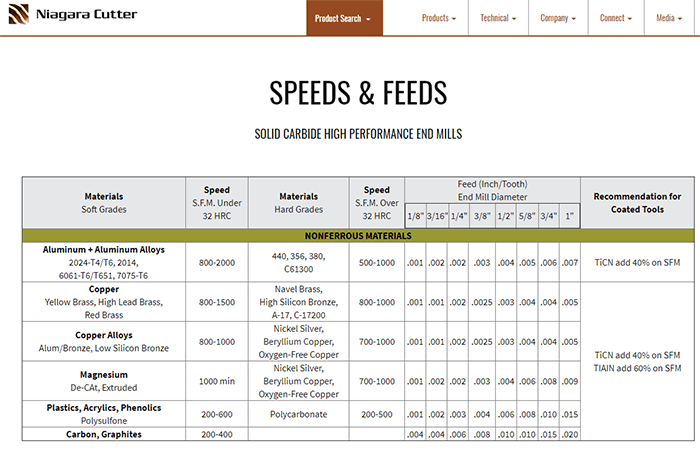

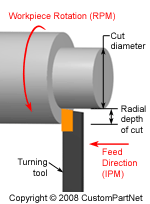

Turning Speed and Feed Calculator Determine the spindle speed RPM and feed rate IPM for a turning operation as well as the cut time for a given cut length. End Mill Speeds And Feeds Chart - Uncoated Carbide. These calculations are based upon theoretical values and are only intended for planning purposes.

F inmin 750 rpm 2 0004 inrev 60 inmin. Determine the spindle speed for turning milling drilling and reaming with these charts and cutting speed calculators. Free Machining Plain Carbon Steels Resulphurized AISI B1111 B1112 B1113 1113 1119 1212 1213.

Machining Speeds and Feeds Calculator. The Speeds and Feeds Calculator uses the following formulas. Free machining plain carbon steels.

Values found in tables will not work for every operation be-cause many variables influence the cutting speeds that can be used. Machine Tool Speeds and Feeds. Turning speeds are adjusted to the feed rate of the mini lathe 0004rev a depth of cut of 0040 and a tool life of 180 minutes.

First is the formula to find the RPM RPM SFM X 382 diameter of the tool SFM Surface Feet per Minute You can also use the RPM calculator below. RPM 12 Surface Speed PI Tool Diameter revsmin Feed Rate RPM Chip Load Number of Teeth Flutes inmin Where PI is the constant 3141592654. Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs.

SMM SFM X 3048. Average cutting speed expressed in meter per minute for different operations in a lathe using an HSS. Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds in revolutions per minute to operate the.

100 to 150 150 to 200. Equations and Explanation Behind this Calculator. AISI 1108 1115 1118 1120 1126.

Turning operations remove material from a rotating workpiece by feeding a single-point cutting tool axially along the side of the workpiece. Recommended Speeds sfpma Material Drill Lathe Mill Magnesium 300 400-800 200-400 Aluminum 250 350-700 250-500 Brass Bronze 200 250-500 150-450 Copper 70 100-250 100-200 Cast Iron soft 120 100-250 80-120 Cast Iron hard 80 50-150 50-100 Mild Steel 110 100-250 70-120 Cast Steel 50. Optimizing feed rates and speeds.

The exact RPM is not always needed the following calculator formula may be used to estimate the value closely. Lathe Rpm Chart Hoskin. Next the formula for the feedrate uses the RPM from the previous calculation Feedrate RPM X Feed per tooth X Number of teeth.

Cutting Speeds and Feeds 31 Cutting Speeds Correct cutting speeds are critical to any lathe operation and have been tabulated for many different machining conditions see the Machinery Handbook. Written by Kupis on January 12 2019 in Chart. Turning Speeds Feeds - RPM Calculations.

This calculator will determine speeds and feed rates for machining operations on mill or lathes. Feeds and speeds formula. The RPM calculated in the TurningLathe Speed and Feed Calculator refers to the spindle speed in turning process and the IPM refers to feed rate.

A feeds and speeds calculator starts with its own internal tables of what the chiploads surface speeds tweaks for different materials and all the rest should be. Feeds - IPT. Lathe Rpm Chart Hoskin.

Cnc cutting tool sds feeds lathe hine parts unit 2 sd and feed manufacturing end mill feed and sd chart caytos cnc cutting tool sds feeds. N rpm 05 1500 rpm 750 rpm. Then decrease speed by 10.

Use the recommended cutting speed charts in Table 4. Machine Tool Speeds and Feeds. Thats a database and the best calculators will make it possible to calibrate that database with your experience your tooling and your shops best practices.